行业未来

Trend

China's manufacturing industry is currently in a transitional period (transition from the industrial 2.0 and 3.0 era to the industrial 4.0 era). Traditional manufacturing has gradually transformed to smart manufacturing. The core carrier is the smart factory derived from the assistance of ICT companies, software companies and equipment automation companies. Under the trend of intelligence, manufacturing companies must choose strategies based on the actual conditions of their technology applications and gradually improve the digital and intelligent level of their factories.

行业面临

Challenges

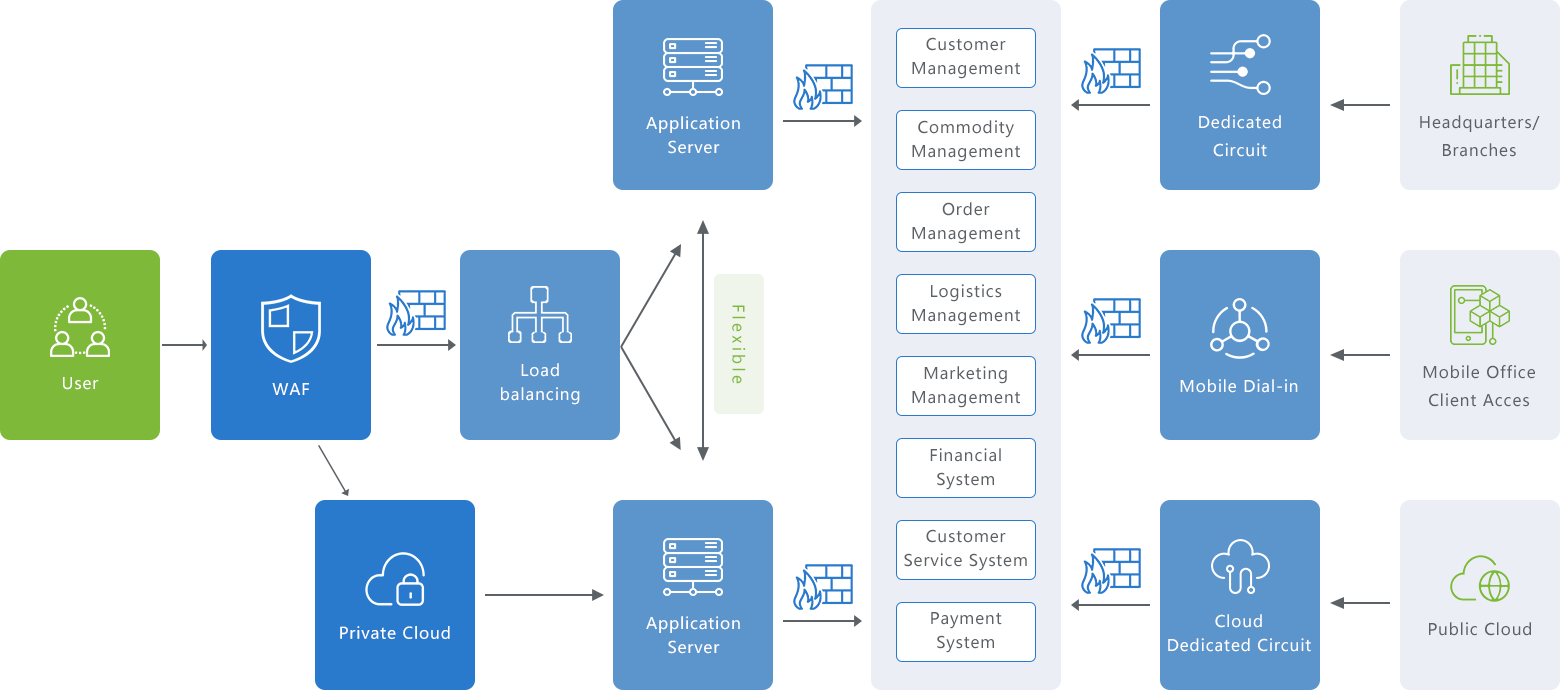

The core of Industry 4.0 is the synchronization of information technology and communication. Enterprises still have great difficulty in realizing the digitization of the manufacturing process, the automation of manufacturing information flow and the collaborative work of multi-business systems.

The enterprise’s informatization foundation is poor

and its business data is not comprehensive;

It is difficult for enterprises to process the data

of production line equipment and terminals in real time;

There are bottlenecks in remote data synchronization.

3.The central site cannot achieve network QoS. Non-critical applications seize bandwidth, causing the bandwidth of critical application systems to not be guaranteed.